GN Solids Control Equipment,Solids Control System

Advanced Screw Press Dewatering Technology from GN Solids Control

In today’s environmental and industrial landscape, effective sludge management is essential. Whether in municipal wastewater treatment plants (WWTPs), industrial waste treatment, mining tailings, or food processing facilities, operators are continuously seeking solutions that combine efficiency, reliability, and sustainability.

One of the most advanced and energy-efficient solutions in solid-liquid separation is the Screw Press Sludge Dewatering System, and GN Solids Control has become a leading manufacturer in this field.

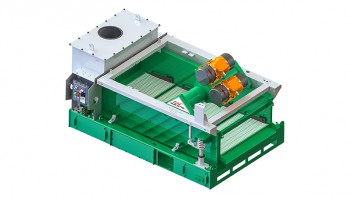

How the Screw Press Technology Works

The GN Screw Press is based on a continuous dewatering process that utilizes a rotating screw shaft within a fixed stainless-steel cylindrical screen. As sludge enters the feed zone, it is gradually compressed by the screw’s pitch reduction and the built-in backpressure plate.

This controlled compression gently squeezes water out of the sludge through the fine screen openings, resulting in high solid recovery and a significant reduction in moisture content.

The system integrates automatic polymer dosing, ensuring the flocculated sludge forms strong, filterable flocs that enhance the dewatering performance.

Key Advantages of GN Screw Press Systems

-

Low Energy Consumption: The slow rotational speed of the screw minimizes power usage compared to traditional belt presses or centrifuges.

-

Low Noise and Vibration: Ideal for continuous operation in municipal or industrial environments.

-

Minimal Maintenance: No high-speed bearings or complex hydraulics; all components are durable and easy to service.

-

Compact Design: The modular system saves space and allows easy installation or retrofitting in existing facilities.

-

Automatic Operation: Fully PLC-controlled with remote monitoring capability for unattended operation.

-

Material Options: All major wetted parts are made of SS304 or SS316, ensuring long-term corrosion resistance even under harsh conditions.

Applications Across Industries

GN’s Screw Press Dewatering Systems are widely applied in:

-

Municipal Sewage Treatment Plants (WWTPs): Efficiently handles excess sludge with consistent dry cake output.

-

Industrial Wastewater Treatment: Suitable for chemical, petrochemical, textile, and metal finishing industries.

-

Food and Beverage Plants: Reduces water content in organic sludge such as dairy, brewery, and meat processing waste.

-

Mining and Mineral Processing: Treats tailings and fine slurry, improving water recovery and reducing disposal volume.

-

Paper Mills and Pulp Industry: Ideal for fibrous sludge with high moisture retention.

Integrated Dewatering Packages

GN Solids Control provides complete dewatering solutions, not just standalone equipment. A typical GN Screw Press system includes:

-

Screw Press Main Unit

-

Sludge Feed Pump (Progressive Cavity Type)

-

Automatic Polymer Dosing System

-

Control Panel and Sensors

Each system is designed and customized according to client specifications, sludge characteristics, and process capacity requirements.

Why Choose GN Solids Control

With over 15 years of experience in solid-liquid separation, GN Solids Control has developed advanced technologies for various industries. The company’s screw press systems are manufactured under strict quality control standards, ensuring reliability, performance, and long service life.

By adopting GN’s screw press technology, clients benefit from lower operational costs, reduced sludge disposal volumes, and improved sustainability — a perfect balance between performance and environmental responsibility.

For more information, visit www.gnsolidscontrol.com or contact GN Solids America for local technical support.